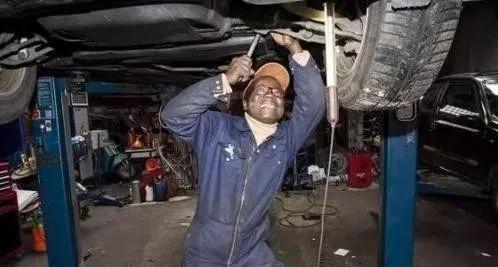

Not only does every family have its hard-to-read scriptures, but every area of life has it, and same is true for car maintenance. Every car repairman starts as an apprentice, experience is thorny, process is frustrating, and few endure.

Xiao Sun, a relative of a friend, had just graduated from a secondary vocational school majoring in car maintenance, so immediately after graduating, he set out on a path of growth as a car repair apprentice. The author recommends, whether it is machine repair, electrical, sheet metal or spray painting, start with simplest, touch everything, repair everything, and then after three or two find development that suits him. years direction. Anyone who comes to auto repair industry should be mentally prepared not to be afraid of hardship, fatigue and dirt, because car repair is hard work.

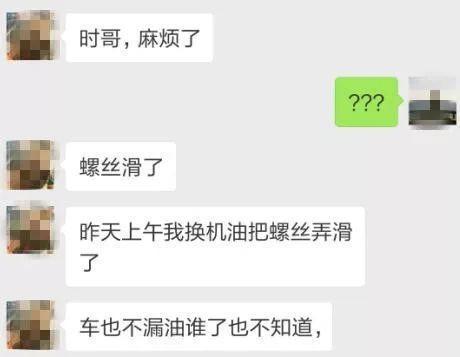

At first everything went smoothly. A month ago, a student of Xiao Sun told author that he could do some simple maintenance projects by himself, but an unforeseen situation disturbed all peace. Recently, author received a message from Xiaosun asking for help saying that he was in trouble. It turned out that during a simple maintenance operation to change engine oil, when old engine oil was drained and oil drain bolt was tightened, Xiao Sun was worried that screw would not be tightened, so he applied some force back and forth. , and thread jumped off. Subsequently, out of nervousness and fear, Xiao Sun did not dare to speak after slipping, but continued to follow procedure of changing engine filter and filling in engine oil. Despite fact that oil drain bolt was turned out, there was no oil leakage, and even car owner did not notice this at one time.

At time, it was considered chaotic, but later Xiao Sun was always troubled by his conscience and asked author what to do. In fact, in such a situation, you can use a tap for secondary threading, and steel wire threaded bushing is used with high precision. In principle, there is no need to replace oil pan, and losses can be minimized. Now that engine oil has been changed, even though there is no leak, it will definitely not work to remove it normally for next change, and there is no guarantee that there will be no oil leakage in future. At that time, early treatment could have saved this box of engine oil and engine filter. The threads on oil pan were thin and could not withstand much torque at all. The oil dangles upwards.

As a student with no experience, there will be flaws in work, but it is important to take it easy, not take risks. What he needs to do now is notify car repairman at auto repair shop. and contact owner of car as soon as possible to fix it.

While what you get in return is doomed to fury, but in end there is a way, and you must observe professional ethics, and you must observe basic principle of life - honesty.

In auto repair, not every thread is tightened like a tire bolt. With exception of oil drain bolt, same is true for oil filter and spark plug. There is a standard tightening torque as stated in this article. Oil drain bolt torque is typically around 30Nm, Oil filter torque is typically around 20Nm, and spark plug torque is typically 25-30Nm > >. In addition, sensors such as knock sensors, oxygen sensors, and water temperature sensors also have their own tightening torques. If torque is exceeded, wires may slip. Using a torque wrench can effectively prevent slippage from occurring.

In addition to using a torque wrench, sometimes you should not recklessly run into obstacles in process of tightening. The bolt is probably misaligned and misaligned. Even just disassembling and assembling bolts is actually not easy. Perhaps experience of Apprentice Xiao Sun will not hinder him, and will be more useful for his future growth.